Aluminum Plate wall panelling is popularly used by architects, designers and building contractors. These lightweight yet sturdy aluminium wall panels are widely used for exterior and interior wall cladding, signage, signage boards, column covers, canopies, and other architectural elements.

Non-Combustible, Aluminum Wall Cladding Solution

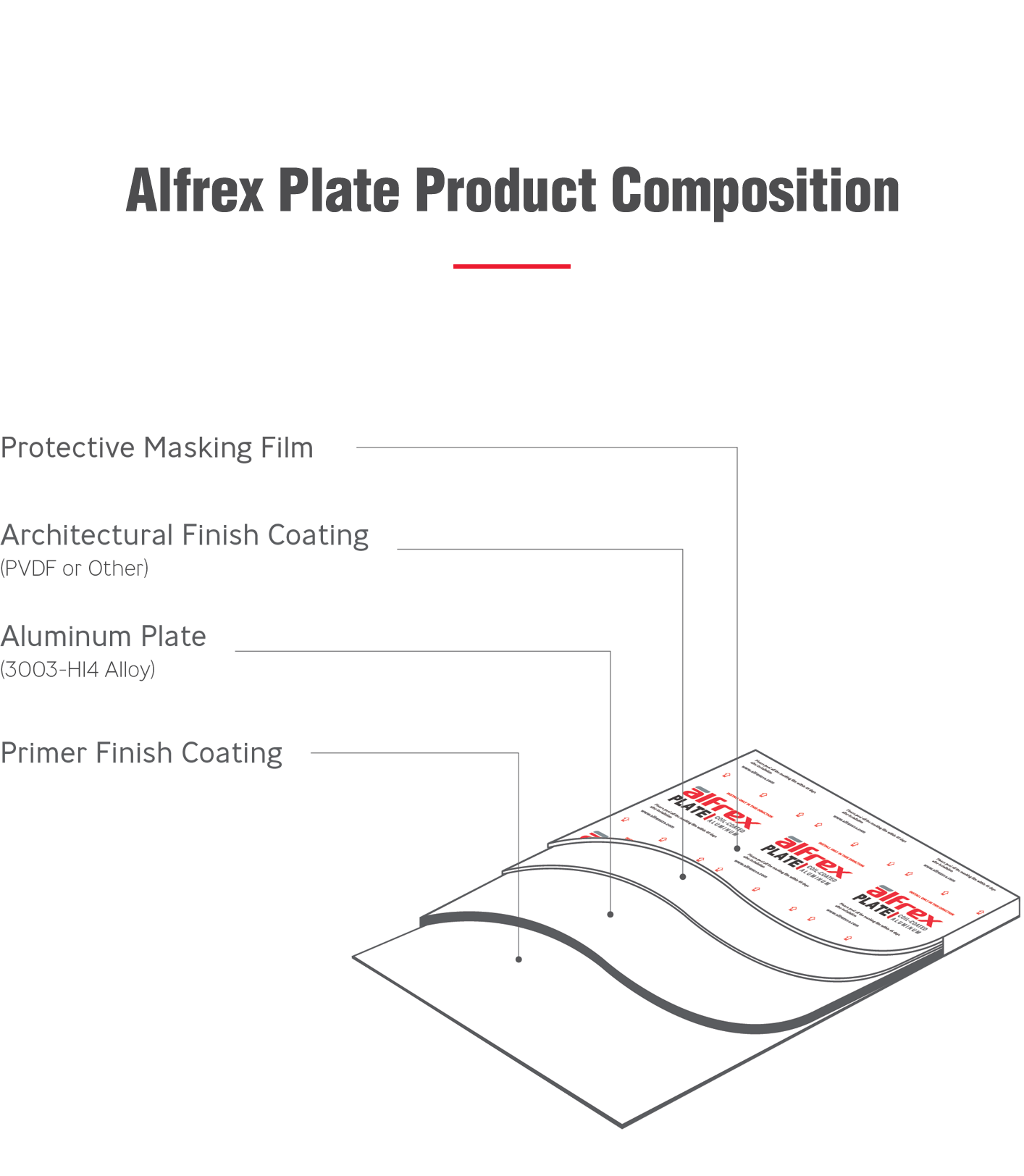

Alfrex Plate is a 1/8” (3mm) pre-finished, 100% solid aluminum, fire-resistant wall cladding panel. It features a nominal standard thickness of 0.125” (3mm) by a maximum 62” width and is available in other popular thicknesses as well as custom widths.

It is pre-finished by coil coating lines specialized in handling heavier gauge solid aluminium coil, then tension leveled and cut to length per the requirements of each project by Alfrex.

Its 70% PVDF Kynar resin paint system ensures color consistency and outstanding UV protection, while it can be coated in coordination with Alfrex FR ACM and matching Flat Sheet in standard or custom colors.

The backside is primer coated to minimize oxidization and enable post-paint spray coating for small lot custom colors, where either air dry or baked finishes are desired.