Architects, project managers, and other industry professionals have the responsibility of designing beautiful structures that function flawlessly while still protecting the safety and welfare of the building occupants. In recent years, several high-rise building fires in other areas of the world have underscored the importance of understanding the fire performance rating of exterior wall cladding assemblies.

It’s important to note that the use of combustible components of exterior wall cladding assemblies is inevitable as without them, design possibilities and targeted performance would be severely limited.

For this reason, the USA and Canada have developed stringent building codes and extensive testing requirements for wall cladding materials. However, the building codes themselves can be complex and confusing at times as they dictate where and how materials may be used in exterior wall assemblies. This is especially true for Metal Composite Material (MCM), where the question of standard polyethylene PE core or fire-resistant FR core comes up frequently.

MCM Core Type: Fire Rating vs Fire Performance

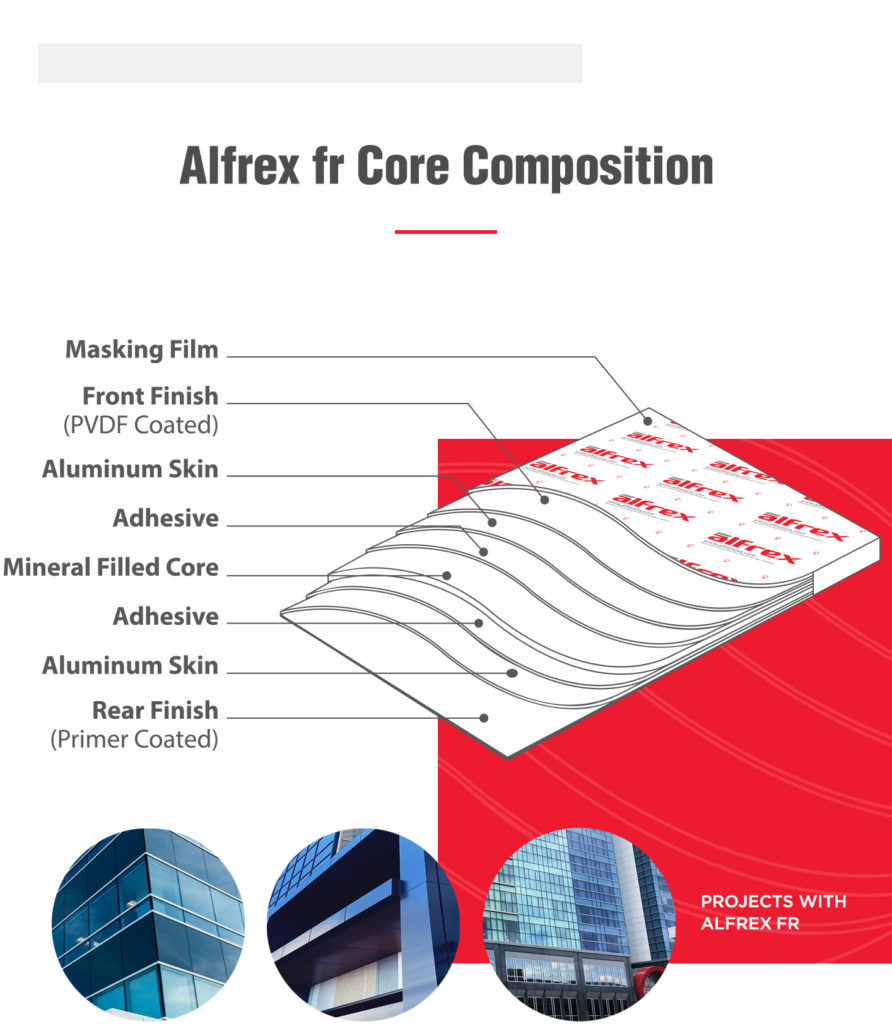

Let’s start with the fundamentals. MCM consists of two metal skins permanently bonded to a solid extruded core material, creating a strong, lightweight, and flexible material ideal for architectural wall cladding.

Two types of core material are commonly used for MCM panels, polyethylene (PE) and fire-resistant (FR). While PE core is a simple polymer, FR core is a compounded mixture of numerous materials specifically designed to limit flame spread by decreasing the amount of available fuel. PE core material is lighter in weight and slightly lower in cost however, its use is limited by building codes.

The use of both core types in exterior wall cladding assemblies is regulated by the International Building Code, Section 1406, where numerous factors dictate the required performance of the MCM panel – which can be complex and confusing to just about anybody.

MCM products on a stand-alone basis must be tested to meet flame spread criteria such as ASTM E84 and Canadian equivalents. However, the gold standard for any combustible wall cladding assembly is the multi-story fire performance test, which is designed to provide performance information for a large-scale multi-story building fire.

In the USA, NFPA 285 is this standard test for combustible wall cladding assemblies while in Canada, NRC/ULC S134, is the required performance standard. Based on many years of experience and testing, only the FR core MCM from any manufacturer can successfully meet the requirements of either NFPA 285 or ULC S134. Therefore, when considering which core material is right for your project and Fire Performance is a consideration, FR Core MCM is the simple and safe choice.

FR Core At Alfrex

At Alfrex, our 4mm thick metal composite material (MCM) is manufactured for architectural building applications utilizing our in-house manufactured, proprietary fire-resistant FR core. It is fully tested, certified, and accredited for use in the USA and Canada, and has passed both NFPA 285 and ULC S134 utilizing both dry-joint rainscreen and wet-seal caulk joint systems.

With manufacturing locations in both the USA and South Korea and over 14 years of MCM manufacturing experience, we supply fire-resistant MCM for projects of any size worldwide. Nevertheless, some municipalities and architectural firms may have particular requirements stipulating non-combustible wall cladding as opposed to fire-performance tested and recognized wall cladding. For this reason, Alfrex Plate is an additional non-combustible option for consideration.

Want to see examples of Fr core in action? Discover our projects

About Alfrex Plate

Alfrex Plate is a nominal 1/8” (3mm) pre-finished, 100% solid aluminum, non-combustible wall cladding plate product and is available in a variety of dimensions. It’s pre-finished by coil coating lines specialized in handling heavier gauge solid aluminum coil, tension leveled, and cut to length per the requirements of each project.

Its 70% PVDF Kynar resin paint system ensures color consistency and outstanding UV protection, while it can be coated in coordination with Alfrex FR ACM standard or custom colors.

What makes Alfrex Plate unique is that it is pre-finished, enabling it to be cut, routed, folded, and installed with virtually the same techniques as Alfrex FR core ACM, eliminating the need for post-painting plate wall cladding panels which may lower costs and decrease product lead times

About Us

Alfrex, LLC is a global architectural metal wall cladding manufacturer headquartered in Buford, GA USA. It is specialized in fire-resistant and non-combustible materials with a portfolio including Alfrex FR Metal Composite Material, matching 0.040″ Flat Sheet, coil coated (pre-finished) Alfrex Solid Aluminum Plate, and mill finish solid aluminum plate for post painting small lot, custom colors.

Our manufacturing philosophy is centered on maintaining healthy inventories of MCM sheets and painted coil in all standard paint finishes to enable a nimble and extremely flexible operation that can manufacture made-to-order MCM in both standard and custom colors.

Company highlights include:

- 20+ years of experience manufacturing specialty fire-resistant coatings and materials through its parent company – Unience, Co Ltd.

- 14+ years of experience manufacturing FR core MCM

- Made in the USA – Buford, Georgia Plant Accredited and Fully Operational

- Manufacturing plants in the USA and South Korea

- Commercial offices in the USA and Canada

- > 3 million square feet of Alfrex wall cladding installed in North America

- The only domestic MCM manufacturer with a complimentary line of 3mm thick prefinished aluminum plate.

- Stocked matching 0.040” pre-finished aluminum flat sheet in all standard paint finish colors for use as trim, flashing, and accessories in coordination with Alfrex MCM or Plate.

Whether you have a project in mind, need samples, or simply have a few questions, Alfrex is ready to assist. Contact us today.

50 comments

Pingback:My Homepage

Pingback:STD Test

Pingback:เช่าตู้เกมส์

Pingback:ทางเข้าpg

Pingback:slot99

Pingback:รถบรรทุกอีซูซุ

Pingback:tga168

Pingback:สล็อตเกาหลี

Pingback:ทดลองเล่นสล็อต ฟรี

Pingback:Massage

Pingback:เน็ตบ้าน ais

Pingback:789BET

Pingback:ผลิตเสื้อยืด

Pingback:is weed legal krakow

Pingback:pg slot

Pingback:บริการหวยออนไลน์ของ เว็บ lotto vip ล่าสุด

Pingback:รับนำเข้าสินค้าจากจีน

Pingback:เช่ารถตู้พร้อมคนขับ

Pingback:แว่นกันแดดแบรนด์

Pingback:สล็อตออนไลน์เกาหลี

Pingback:แทงบอลออนไลน์เกาหลี

Pingback:https://www.mechandlink.com/en/device-list/loader

Pingback:Outdoor Cooling

Pingback:highbay

Pingback:highbay

Pingback:thailand tattoo

Pingback:meža pirkšana

Pingback:ของพรีเมี่ยม

Pingback:เช่าที่เก็บของ

Pingback:Open link

Pingback:sagame

Pingback:Image Line Painting 4508 6 St NE Calgary AB T2E 3Z7 +14036131045

Pingback:ปั้มฟอล

Pingback:chimney sweep liverpool

Pingback:lg96

Pingback:pgslot168

Pingback:ซักผ้าอุตสาหกรรม

Pingback:สล็อต เครดิตฟรี

Pingback:Plinko App

Pingback:usa89

Pingback:Codename:Pepe

Pingback:y2k168

Pingback:cardzone.cz

Pingback:frantaskala.com

Pingback:Mostbet

Pingback:Aviator

Pingback:The Intersection of Ethics and Mandamus Law - Writ of Mandamus Law firm

Pingback:The Basics of BIA Notice of Appeal: Understanding the Process - Criminal Immigration Lawyer in NY & NJ

Pingback:Understanding i-797c Processing Time in 2024 - Criminal Immigration Lawyer in NY & NJ

Pingback:Introduction to AAO Appeal - Criminal Immigration Lawyer in NY & NJ