Alfrex Plate Harnesses Contrasts in Color, Shape, and Light on The Works Project

A rapid revitalization is underway in Atlanta’s Upper Westside, an area historically characterized by industrial manufacturing, warehouses, and rail lines. Anchoring this transformation is The Works, an expansive 80-acre mixed use development blending office space, residential living, retail, and dining – while preserving the district’s historical industrial character. Guided by the vision of Selig Developments and designed by Smith Dalia Architects, the completion of Phase One showcases a parking garage remarkable for its unique design and complexity.

| Project Name | The Works Parking Garage |

| Location | Atlanta, Georgia USA |

| Developer | Selig Developments, a subsidiary of Selig Enterprises, Inc. |

| Architect | Smith Dalia Architects - Atlanta, GA |

| General Contractor | Dakota Contractors, LLC. |

| Fabricator | MillerClapperton |

| Installer | MillerClapperton |

| Alfrex Product | Alfrex Plate - 3mm Pre-Finished Solid Aluminum Plate |

| Product Finish | PVDF Custom White over PVDF Custom Orange (Double Sided Finish) |

A rapid revitalization is underway in Atlanta’s Upper Westside, an area historically characterized by industrial manufacturing, warehouses, and rail lines. Anchoring this transformation is The Works, an expansive 80-acre mixed use development blending office space, residential living, retail, and dining – while preserving the district’s historical industrial character. Guided by the vision of Selig Developments and designed by Smith Dalia Architects, the completion of Phase One showcases a parking garage remarkable for its unique design and complexity. Canvassing the garage is 13,025 square feet of 3mm thick Alfrex Pre-Finished Solid Aluminum Plate from Alfrex, LLC of Buford, Georgia USA. Fabricated and installed by MillerClapperton of Austell, Georgia, the façade is intricately designed to harness contrasts in color, shape, depth, and light to create stunning views both day and night.

The Challenge

MillerClapperton recognized early on that this complex project would require custom solutions on all facets of execution from product choice, engineering, fabrication, and installation. Façade panel design called for a product that could be perforated in large areas, folded into geometrical shapes, coated orange and white on opposite sides, and capable of sustaining structural loads. This semi-transparent façade assembly then had to be attached to existing blue colored vertical steel beams in a manner that did not interfere with the architect’s design vision. A significant research effort was undertaken to develop a simplified sub-structure for wall panel installation that would create an interplay between the exterior façade without distracting from the design in an array of lighting conditions.

Product Choice – Alfrex Plate

Alfrex Pre-Finished Solid Aluminum Plate in a 1/8” thickness was chosen due to its ability to meet the diverse aesthetical, structural, and economical requirements. Alfrex Plate is coil coated on a high-speed paint line designed specifically for heavier gauge metals. As such, it was very efficient to manufacture sheets double coated with a custom white paired opposite a custom orange. This enabled sheets to be custom fabricated, folded, and oriented to create color contrasts using the same panel without welding or additional field painting. Further savings were realized through scrap reduction as Alfrex Plate sheets were manufactured in a custom width and provided in numerous custom lengths via its integrated coil coating, tension leveling, and cut-to-length process.

Sheet Fabrication and Engineering

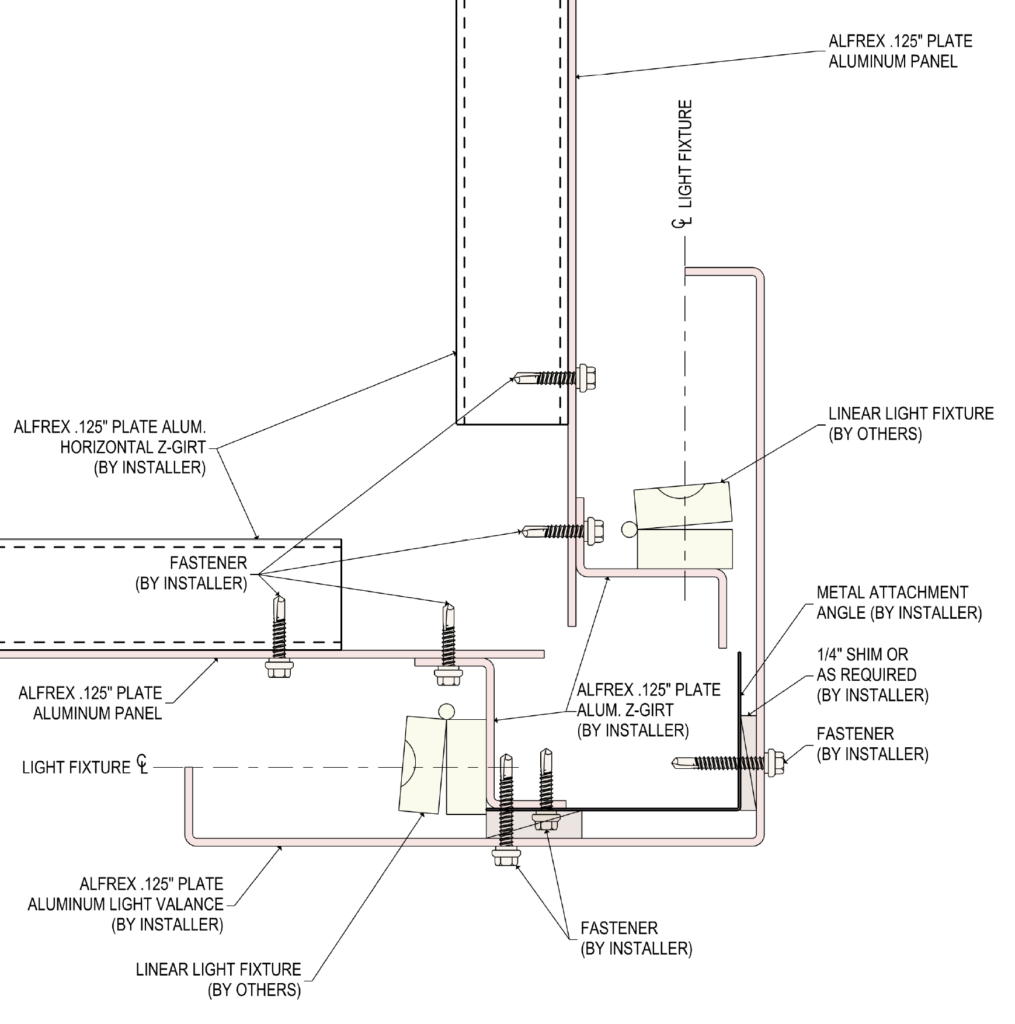

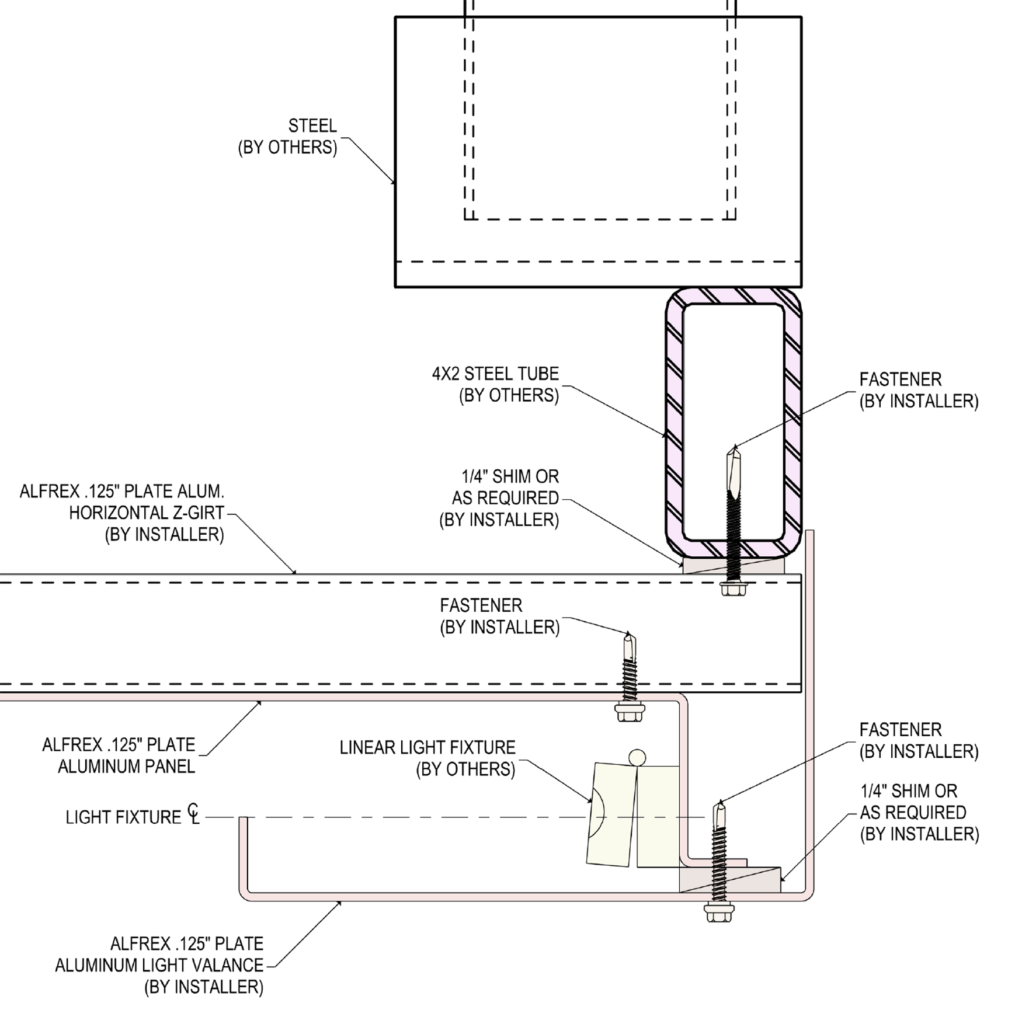

For the large number of perforated panels, custom tooling was developed to punch press perforated sheets of Alfrex Plate with 1.5” diameter openings. Sheets were then cut to size and back routed to enable folding into 3-dimensional geometrical shapes. As a prefinished product, Alfrex Plate was able to be cut, routed, and formed much like MCM panels without additional steps or danger of paint finish crazing. For panel installation though, a wall façade with large perforated areas and openings presented both an engineering and aesthetical challenge requiring a unique solution.

To achieve this dual requirement, custom 1.5” Z-Girts were fabricated from Alfrex 3mm Plate and attached horizontally to the garage’s vertical beams. This provided not only a structurally sound means for installation, but also an aesthetical solution by capitalizing on the double side coated Alfrex Plate sheets to integrate seamlessly into the façade’s color and design scheme.

Custom Light Valences

Considerable effort was put into the design and integration of custom light valences manufactured from Alfrex Plate. The light valences are effortlessly integrated into the façade design and accentuate nighttime views of the building.

The Result

The Parking Garage at The Works stands out as an interconnected part of a broad development project thanks to its unique design and choice of materials. “I’m thrilled with the outcome of the project – the rigorous design process with the client, design team, and fabrication team paid dividends in the cohesive manner that everything came together”, said Nicole Seekely, the Project Architect. “The color of the panels provides an added level of artistic expression to the façade, particularly on a sunny day when the light casts shadows on the panels.” The flexibility of pre-finished Alfrex solid aluminum plate enabled fabrication and installation much like MCM metal composite material, cutting down on waste, fabrication time, and an efficient means of color coating.

Alfrex specializes in fire-resistant and non-combustible architectural metal wall cladding with a portfolio including Alfrex Pre-Finished Solid Aluminum Plate, Alfrex FR Metal Composite Material, and Matching 0.040” flat sheet. Its parent company, Unience, Co Ltd., began operation in 2000 as a manufacturer of specialty fire-resistant coatings, bonding materials, and pelletized mineral filled FR core compound for globally recognized MCM manufacturers. In 2008, Unience launched Alfrex in South Korea with a multi-line MCM production facility dedicated to the exclusive production of FR core MCM utilizing in-house, fire-resistant core technology. Today, both Unience and Alfrex are headquartered in Buford, Georgia USA, with a new state of the art FR core MCM production plant complimented by a commercial branch in Toronto, Ontario Canada.